How technology is providing a VIP shopping experience for all Q&A with Nadia Akil, CEO of UPAC

E-commerce is disrupting the retail sector. Its growth potential is huge in the GCC, as e-commerce has been slower to gain a foothold here compared to more mature markets. The market is expected to double to $20 billion by 2020.

So what does this mean for brick-and-mortar retail? Malls are a crucial part of the region’s culture. Will a shift to online buying spell trouble for them? Not likely. In fact, some of the same digital innovation driving the change in consumer buying habits is also transforming shopping malls in the Middle East. It’s time to get ready for the super-sized smart mall.

To find out more, we spoke with Nadia Akil, CEO of UPAC, an Agility affiliate and leading investor in Reem Mall, a $1.2 billion retail leisure, dining and entertainment destination set to open in Abu Dhabi in 2020.

What is your take on the changing retail landscape in the Middle East?

It is drastically different from ten years ago. The rise of e-commerce is a huge challenge for retailers. Although its uptake has not been as rapid as in the U.S. or U.K. — e-commerce still counts for just 2% of retail sales in the Middle East — that’s only going to increase. We’re living in a digital world, and brick-and-mortar retailers must embrace this if they’re to survive. I’m not just talking about having an online presence. Retailers need to move to a smart model where the physical act of shopping is combined with a digital experience. As a retailer, you need to look at the customer journey and use technology to improve it and, most importantly, make it personal to them.

How can retailers use technology to improve the customer experience?

Augmented Reality (AR) is a great example of how technology can improve the customer in-store experience. Sometimes when browsing clothes you want to see what they look like, but don’t want the hassle of actually trying them on. Shops can offer an AR experience through augmented dressing rooms, or via a smartphone app. AR is already a hit with consumers – according to a study by Interactions , 61% say they would prefer to shop at a store that offered AR over those that don’t.

If shoppers enjoy trying items on but want a better experience, smart mirrors are the answer . Interactive fitting rooms kitted out with “magic” mirrors automatically recognise products through RFID tags. These are synched with store inventories, so if a customer wants a different size or style they can request it. The mirror image can also be captured on camera, allowing the shopper to easily seek a second opinion from friends via social media.

Robots aren’t being utilized past the self-checkout stage for now, but it’s only a matter of time before consumers can enjoy their own “personal shopper” robot in store.

And what about personalizing the customer journey?

Data and analytics play a key role here. Retailers who have an online offering can use this data to encourage their customers to visit the store through personalized promotions. Physical stores can also maximize on the point of sale, encouraging consumers to spend more by sending targeted offers to their mobile phones through digital signage, and based on what they’re trying on in the dressing room or have in their baskets.

Personalizing the customer journey will be crucial to the survival of physical stores because it’s everything from the customer’s perspective. Nearly all consumers (91%) are more likely to shop with brands that recognize and remember them, and that provide relevant offers and recommendations, according to a study by Accenture.

How else is technology transforming the process?

Retailers need to be able to rely on super-efficient supply chains. If they don’t have a product a customer wants in stock they need to be able to get it to them ASAP. Shoppers who want purchases delivered to their doors need retailers with super-fast delivery services.

In response to this need, technology is transforming the logistics sector and enabling it to operate at high-speed. Warehousing is more efficient thanks to big data, automation and robotics. The challenges of the last mile are being overcome by the gig economy and SMEs who collaborate with retailers to ensure last-mile delivery in under an hour.

What about the rise of the super-sized smart mall?

In the Middle East, the mall is so much more than a place to shop. Malls are a key part of our culture, places you go to spend time with your friends and family. But to survive in the digital world they must embrace technology and use it to enhance the visitor experience.

In the smart mall, technology is everywhere. From the digital and interactive signage throughout to the tablet you order your lunch from in the food court. Malls can enhance the experience with apps that engage customers by letting them know about events at the mall, the latest offers and promotions in stores, and helping them locate services and find friends who are also visiting that day.

We’ve touched on AR, but VR (Virtual Reality) is also an exciting way for malls to offer immersive experiences to visitors. VR lets customers try out products in a way they couldn’t anywhere else, taking the retail experience to a new level. Say you’re buying an outfit for a special occasion, VR allows you to try it on and test it out “on location.” Buying new sports equipment? VR puts you on the tennis court or golf course, ready to swing your racket or club.

Smart malls can also overcome pain points for shoppers by offering parking assistance and delivering purchases to cars to free up shoppers throughout the day.

Finally, malls should be mindful of social media opportunities and integrate these into their design and layout. You need Instagram-friendly displays, and interactive features that users can synch with their social media accounts.

And what about “retail-tainment”?

Consumers want bigger and better experiences and this is where mega-malls come into their own. Their sheer size makes them destinations in their own right.

At Reem Mall in Abu Dhabi we will be offering a range of entertainment activities such as Snow Park Abu Dhabi, the region’s largest indoor snow park where visitors can enjoy sledding, luge runs and zorbing! In a mall! Now that’s an experience. Reem Mall will also be home to the award-winning VOX Cinemas, including the large format MAX screens, fine dining Theatre by Rhodes and the children focused VOX Kids. For the first time, VOX Cinemas will be fused with Magic Planet creating a unique leisure destination. In addition, Reem Mall will house a variety of around 100 food and beverage options ranging across fine dining, family style, casual dining, cafes, fast food, pâtisseries and coffee shops, all located throughout the mall.

Malls really are places where the family can spend a whole day together being entertained, and where friends can meet to relax and socialize. E-commerce can’t take away from that, but retailers can future-proof their businesses by embracing technology and offering customers an enhanced shopping experience as part of the visitor’s day out.

Thanks Nadia. It sounds like, ultimately, the customer will benefit most?

Absolutely. Disruptive technology is challenging the physical retail sector to up its game, and that’s a great thing. Through digital integration smart malls are offering a VIP shopping experience to all, which I for one will be embracing!

Warehousing is in the midst of a tech-driven revolution as companies race to identify and adopt emerging technologies that cut costs, optimize operations and improve overall supply chain efficiency. In some of the largest economies and companies, warehouse drones and robots already have been employed.

It’s not just logistics giants who are adopting innovative tech-based solutions. With the cost of automation falling, increasing numbers of SMEs and startups are investing in these efficient technologies. The top nine technologies shaking up the traditional warehousing scene:

1. Drones to automate inventory and asset management

Small maneuverable drones are appearing in warehouses as companies around the world seek to automate inventory and asset management. With stock stored up to ceilings as high as 12 meters in many warehouses, hard-to-reach barcodes have traditionally meant hours of labor using equipment such as forklifts and ladders. Scanner-carrying drones increase speed and accuracy by navigating warehouse shelves and taking automatic registry of stock. RFID tags can be read and located through cameras from a distance of 10m. Still needed are advancements that allow numerous drones to navigate tight spaces without colliding.

2. Robots for automated order packing

Robots are a game changer. They are programmed to guide themselves and to pick and pack orders into waiting carts or trucks. Some warehouses have already made the shift to full automation through use of robots. The distribution warehouse at online British supermarket Ocado uses thousands of robots to pack groceries into individual boxes. The robots run on complex algorithms that teach them where to pick up inventory and guide them to the exact grocery bag to drop it into, all while making sure that they don’t collide as they roam around filling orders.

3. Better batteries to improve efficiency

Batteries might not seem directly linked to warehousing, but they can power the machines that facilitate warehouse operations. So how can the latest innovations in battery technology advance warehousing?

Advancements in lithium-ion power cells have created impressive battery lives that can last up to ten years before needing to be replaced. Tesla’s latest batteries focus on alternative and affordable energy sources, drawing on solar power and energy from nearby power grids. Just think how powerful, efficient and cost effective robots, electric forklifts and other warehouse machines could be if they utilized these battery technologies. Heating and cooling warehouse space can consume large amounts of energy, so using improved batteries to power these systems could also mean significant savings on this front.

4. 3D Printing

3D printing could shake-up the entire global supply chain by bringing manufacturing closer to consumers and other end users. Take the example of auto parts now made in Asia for vehicles assembled in Mexico and sold in the United States. Production of some parts is likely to move closer to the market to cut down on shipment times and costs. 3D printing could reduce costs associated with complex trade and customs red tape for vast amounts of goods, because they could just be printed on demand near their final destination.

5. Automated Guided Vehicles

Automated Guided Vehicles (AGVs) differ to robots because instead of operating more autonomously they follow guided routes around warehouses. A huge advantage of AGVs is that they replace forklift trucks, so it’s not necessary to change the basic configuration of a warehouse. AGVs are also designed to come to a safe stop if they run into anything. This increases efficiency as AGVs can run continuously without breaks. AGVs are expected to become practical in even the smallest distribution centers, such as those of SMEs, as their cost continues to decrease.

6. Cloud Technologies

As with other industries, cloud storage is revolutionizing the productivity of warehousing as the instantaneous and self-updating systems cut down maintenance, infrastructure and the labor costs associated with the upkeep of management systems. Cloud technologies are also user-friendly and can be used by all employees, leaving companies less vulnerable if highly-skilled tech workers move on.

7. On-demand Warehousing

The “uberization” of warehousing – on-demand warehousing – is an emerging way of buying warehousing services and space on a pay-per-use basis. This method of warehousing gives customers more choice and flexibility over location, cost and supplier, either as a complete substitute to owning warehouses, or as partial replacements when new warehousing locations become necessary. The biggest disadvantage logistics companies face when adopting on-demand warehousing is that they’re exposed to fluctuating market rates for space, which is often overpriced in locations near ports, airports, rail spurs, major roads and urban centers.

8. Internet of Things

Internet of Things (IoT) technologies are not new on the logistics scene, and devices such as wearables, sensors and radio-frequency identification tags (RFID) are already used in many warehouses. By communicating relevant information to other IoT devices, the technologies reduce human error and the need for manual labor. Warehouse managers also get real-time visibility of order fulfillment, allowing them to process goods more efficiently.

Security concerns have blocked some of these advancements from reaching their potential, but a number of emerging technologies are being developed to enhance the safety of applying IoT sensor technology to large logistics operations. Microchips that allow more efficient encryption are one of the innovations that will ease security concerns about adopting the IoT in warehousing, and drastically increase efficiency in the future.

9. Composite Panel Technology

Clever developments in the construction and maintenance of warehouses are set to optimize insulation, air-tightness and durability through the use of new materials in composite panels. The latest panel technology can improve warehouse energy efficiency by around 20%. The cost and emission savings will be especially important in cold-storage facilities such as chilled and frozen food warehouses, where maintaining the correct temperature requires significant resource.

Composite panel technology is set to have global impact on the logistics supply chain: not only does it increase sustainability, it can also decrease warehouse build time and costs by one fifth.

After many years in early stage venture capital funding, I’ve seen the good, the bad and the ugly of the startup world. There are a few things that almost all successful entrepreneurs have in common, and plenty of mistakes to be avoided as well.

For your best chance of success, here are five tips for establishing a startup that can really go the distance. Plus, if you’re looking for investment, look at my post below, where I share industry insight into the most common ways entrepreneurs accidentally sabotage their funding pitches.

1. Find a co-founder and team with complementary skill-sets

Picking the right co-founder can be precarious and time consuming. Many venture capitalists favor startups with two strong co-founders over those with one, because they are generally considered to have more chance of succeeding. The co-founder model can mitigate risk of burnout and makes it less likely the company will collapse if a key figure leaves.

Each principal should ideally bring a unique skill set and lead a different section of the business. For example, one co-founder might guide the technological side of the company, while the other heads up finance and operations. In this scenario, each co-founder tends to be more passionate about their section of work, and brings highly specialized knowledge that complements the other’s, optimizing the efficiency of business operations.

But while there are undeniable benefits to having a co-founder by your side when the going gets tough, it’s not impossible to succeed by going it alone with a single founder or principal. It is crucial, however, to make sure the team around you has skills and passions that fit well with yours and that you have a really strong second-in-command who you trust to make decisions and lead when needed.

Being the sole founder of a company also makes it even more important to have structures in place to ensure that your wider team is incentivized to work hard – usually this is very effectively achieved through equity ownership.

2. Build a team that can do it all

Whether your team is tiny or substantial, team members must be able to work together and cover all the critical functions of your business without any gaps.

It’s important to make sure all bases are covered, but don’t hire people just to tick a box. Often entrepreneurs replicate traditional management structures, instead of searching for people who can fulfill the functions their company needs.

Staff members who are hungry, multi-skilled and willing to pitch in and fill gaps are invaluable, especially in small- and medium-sized companies. People are any startup’s most valuable asset, so make sure every hire is a great one.

When I recommend a business for investment, what I’m really putting my faith in is the people. A good team is the single most important factor in making sure a startup succeeds. You can have the best idea in the world, but if it doesn’t have good people to make it happen then it will probably fail.

3. Find multiple investors

It’s a good idea to diversify your investment streams as much as possible, even if your business is still in the early stages. The key here is to have multiple sources of capital because delays often need to be resolved with an injection of cash, so having a few parties pitching in additional capital is always good.

Obviously, this can be a challenge. Maybe it was hard enough to find that backer in the first place! But if one investor has faith in you and your ideas then the chances are that others will too.

Lots of new entrepreneurs get complacent once they’ve found their first financial backer, and shift their focus entirely to developing their idea and business. Obviously it’s important to do this as well, but if you stop searching for investment it can lead to problems in the future. With only one backer you might struggle to expand at the rate you’d like, and it’ll be much harder to push back against your original investor if you need to.

Having multiple investors keeps your options more open. And remember that venture capitalists have more to offer than money: each brings a unique set of assets. While some are great at strategy and hiring, others have your domain expertise and can tap into their network to help your company. So it’s worth spending some time to find a broad group of investors who can bring different value to you down the road. You’ll have to answer to more stakeholders, but it’s worth it to make sure you diversify the sources of knowledge you can draw on.

4. Don’t do it just for the money

All entrepreneurs want to make money, and the prospect of financial reward is a powerful motivator. But money hardly ever provides all the motivation you need to keep going through the ups and downs of building a business from scratch.

Make sure you find something that you feel passionate about in addition to making money. You need to be interested in what you’re doing and believe that it offers benefits. If you aren’t sure, how are you going to convince anyone else to buy what you’re selling?

Figure out what motivates you. Is it finding new, more efficient ways of doing things? Is it introducing a completely new product to market? Do you have a passion for utilizing technology to solve problems? What is the purpose of your company?

You will need to care about what you’re doing to overcome the hurdles. Rather than pursuing an idea that could have the biggest profit margins but leaves you cold, pick something that’s financially viable and that you feel excited about – and then the money will follow.

5. Make sure your target market is big enough

You might have the most wonderful solution in the world, but if the problem it fixes only applies to a small universe of customers then you need to turn your focus to something else.

If the market for a new product or service is too small then it will be almost impossible to find investors. No one will take a risk on something with a small potential for returns, and sometimes products and services simply aren’t marketable. Restricted markets certainly aren’t the right territory for entrepreneurs in the early stages of expanding their business.

Depending on how niche the market is, it might be possible to come back to “smaller” ideas when you’ve built your reputation and revenue. If you can integrate them into your business model cost-effectively, then you can make additional profits from them. But start with a focus on ideas that are broad in scope.

Now get out there and win!

It’s never easy. But if you’re on the Agility Ventures website, you’re already a passionate entrepreneur who’s doing a lot right. You’ve picked a market with so much potential – logistics is complex and full of disruption, and that’s what makes it so exciting and full of opportunity. Do your research, make informed decisions and bring the innovations you want to see to market.

Find out more about Victoria Grace and her relationship with Agility here bio box, and keep checking the Agility Ventures site for advice and articles to help you succeed on your entrepreneurial journey.

As environmental, social, labor and governance imperatives come into sharper focus, the business case (again) for putting sustainability at the core of a company’s strategy.

Growing evidence suggests that businesses everywhere are putting sustainability at the core of their strategic thinking, planning and operations after decades of disconnect between their stated objectives and actions.

Sustainability is finally being embedded into business activity. One reason is that corporate data and academic research have begun to show a return on sustainable initiatives and practices, particularly at companies willing to broaden their definition of Return on Investment and adopt longer time horizons.

Another reason is the growing clamor from a spectrum of stakeholders – consumers, B2B customers, insurers, institutional and individual investors, regulators, community leaders, watchdog groups, employees and job candidates – for companies to demonstrate that they are responsible actors.

The sustainability movement is maturing. Considerations about social and environmental impact are shaping nearly every facet of corporate activity – nowhere more than the supply chain.

“Customers used to think about things in isolation like greening a warehouse, measuring CO2, or getting more visibility into their suppliers,” says Mariam Al-Foudery, Agility Group Chief Marketing Officer, who oversees sustainability and corporate social responsibility.

“Now more customers are looking at the whole supply chain and identifying practices that are connected and mutually reinforcing, things that have impact across business units and operational locations over the long-term.”

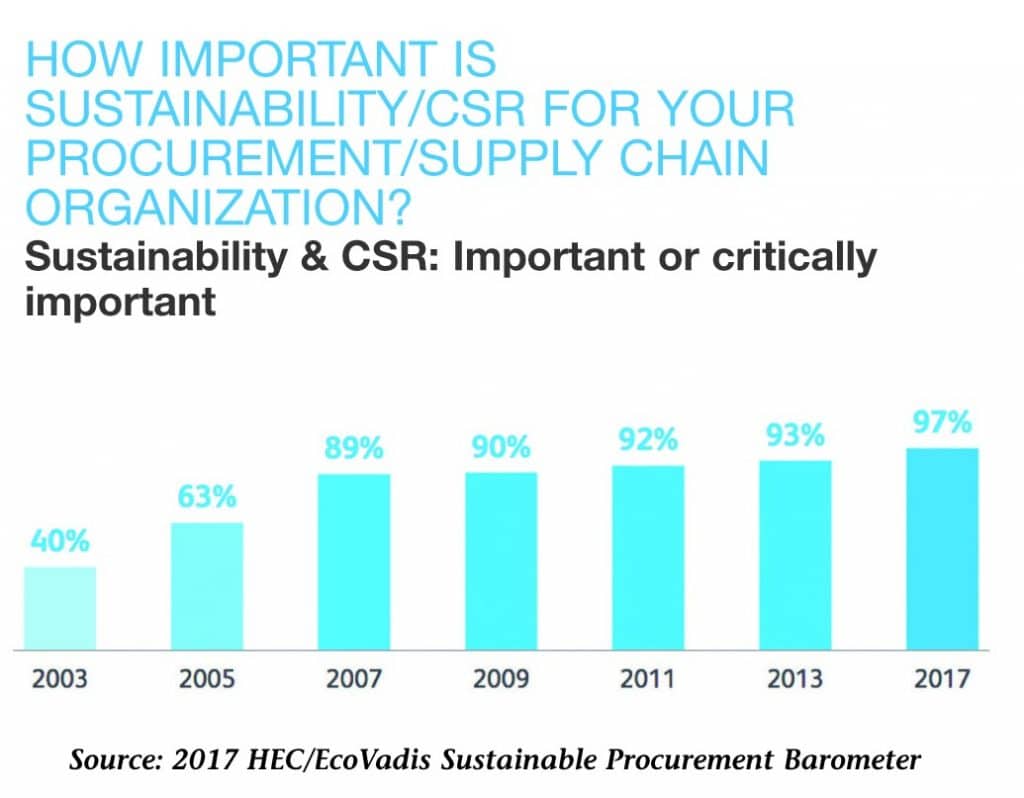

In a 2017 survey by EcoVadis and the HEC Paris business school, 97 percent of procurement officers surveyed listed sustainability as one of their top five priorities. Seventy-five percent of responding companies said they were using sustainability and corporate social responsibility criteria when selecting new suppliers.

What is sustainability?

Sustainable businesses try to meet the needs of the present generation without compromising the ability of future generations to meet their needs. They focus on good treatment of employees, impact on the environment, impact on local communities, and business relationships with suppliers and customers.

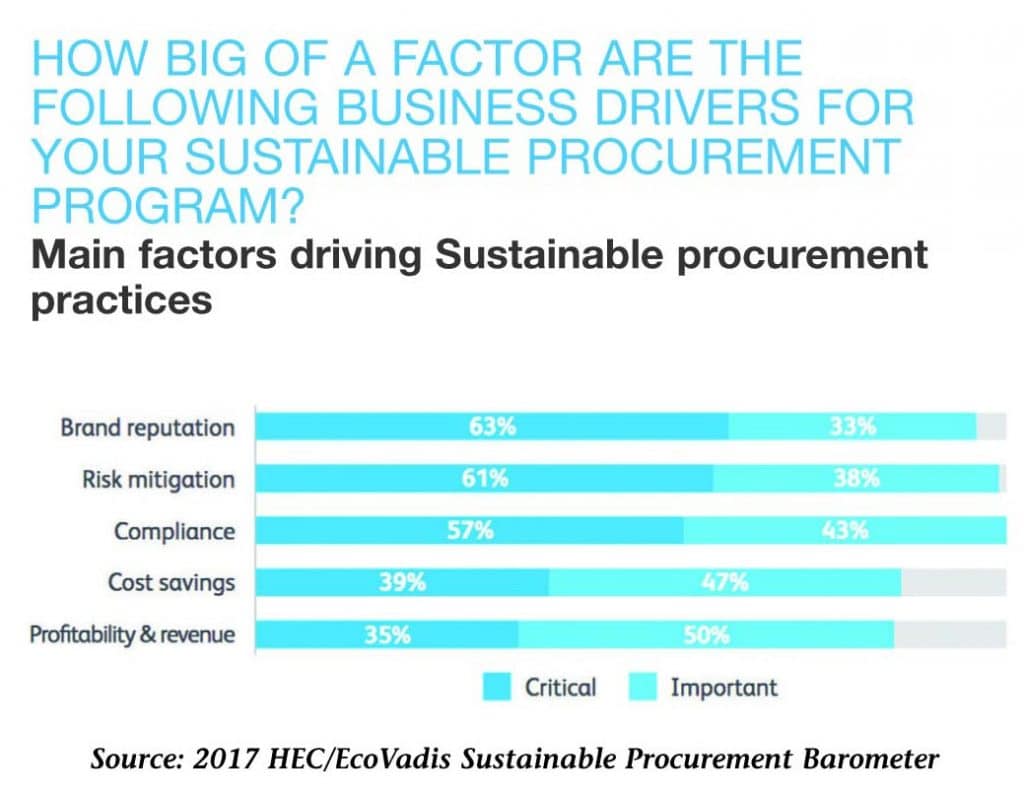

“Sustainable procurement is no longer a nice-to-have – it’s an integral business function responsible for protecting and improving brand reputation, driving revenue and mitigating business risk,” says Pierre-Francois Thaler, co-CEO of EcoVadis, an independent group that provides business sustainability ratings and analysis.

Not everyone is as enthusiastic

Yossi Sheffi, director of the MIT Center for Transportation & Logistics, says sustainability advocates have succeeded in framing the issue as one of “profits versus planet” or “societal good versus corporate evil.” He says that narrative ignores the role of businesses and their supply chains to provide jobs and deliver improved living standards. Sheffi argues that there is a difficult balance to strike and that the real friction is between those demanding environmental stewardship and people who seek jobs and affordable goods.

“Companies are championing their environmental credentials in glossy reports, speeches and media interviews,” Sheffi writes. “At the same time, however, many will admit, off the record, either that they do not believe in the need for this effort, or more commonly, that current initiatives do not meet any reasonable cost-benefit test even if global warming is real and the danger acute.”

Better processes

Others insist there is mounting evidence that sustainability adds real value.

“Embedded sustainability efforts clearly result in a positive impact on business performance,” according to a Harvard Business Review article co-authored by Tensie Whelan, director of the Center for Sustainable Business at New York University’s Stern School of Business. (See Q&A on page 10).

Whelan and her co-authors argue that sustainability delivers significant cost savings from increased operational efficiency and that it drives companies to innovate by creating better processes, new products and equipment, and improved working conditions.

When sustainability is part of corporate DNA, it can “engender enthusiasm from employees, customers, suppliers, communities and investors,” the HBR authors conclude.

The Sustainable Business Council says there is ample research to show that sustainability lowers the cost of capital, results in better operational performance, and has a positive effect on stock price. Sustainability is a major factor in building and protecting corporate value, the SBC says. Consulting firm McKinsey has estimated that the value at stake from sustainability concerns is as high as 70% of earnings before interest, taxes, depreciation and amortization.

“Forty years ago, the bulk of a company’s value linked directly to its tangible assets,” the SBC says. “Now only about a fifth relates to a company’s financial performance and physical assets. The rest reflects intangible assets like brand, intellectual property, and whether a business has a social license to operate.”

When sustainability is part of corporate DNA, it can “engender enthusiasm from employees, customers, suppliers, communities and investors.”

BY 2035: THE CHANGING ENERGY PICTURE

- Fossil-fueled cars will require 40 percent less fuel to go one mile.

- Energy intensity – the amount of energy required to produce a unit of GDP – will be half what it was in 2013. (Traffic congestion can cost as much as four percent of a country’s GDP.)

- Demand for electricity will grow twice as fast as energy demand for transport.

- Seventy-seven percent of new electrical capacity will come from wind and solar; 13 percent from hydro. (Installed cost of solar has fallen by 70 percent since 2009.)

- The population will have grown by 1.5 billion.

Source: McKinsey Sustainability & Resources Productivity

Agility innovation

Like its customers, Agility is taking aggressive steps to get greener. It is working with carriers to slash CO2 emissions, rethinking warehouse construction and management, piloting use of solar energy in building cooling, and investing in energy-recapture technology for trucks.

Mindful of its social impact, Agility pioneered protections and standards for workers in the Middle East more than a decade ago and has been a leader in sharing best practices and publicly advocating for stronger protections. In 2017, Agility introduced its first stakeholder policy, laying out goals and commitments to protect the environment, safeguard workers rights, improve communities where it operates, and be responsive to the needs and concerns of a variety of different interests.

“The biggest challenge for us and most logistics providers is on the customer side,” Al-Foudery says. “Customers want strategies, tools and technology to help them meet their sustainability goals.” One such tool gives Agility customers the ability to compare and optimize the environmental impact and cost of individual shipments using a nearly infinite variety of shipment types, routes, load sizes and configurations, and other factors.

Zero-impact target

A leading apparel powerhouse approached Agility with the goal of building sustainability into the design and manufacturer of its vast, globally sourced product line. Agility worked with the customer to create an information and standards framework and to build measurement and performance targets into its supply chain.

The apparel customer’s objective is a low/zero-impact, closed-loop supply chain: dramatic cuts in CO2 emissions and energy per unit of manufacture; facilities running 100 percent on renewable energy; 0 percent waste; doubling of supply chain efficiency every 18 months to two years.

“That can be scary, but customers with big, ambitious goals are sometimes the easiest to work with because they’re totally committed. They will take risks in order to become leaders,” Al-Foudery says. “They’re ready to innovate and break from established practices and willing to reward partners who help them achieve their goals.”

Sustainability efforts by consumer products companies and retailers typically get more visibility than those of B2B companies.

Alarmed by oceanic pollution, Nestle, Procter & Gamble, Coca-Cola and Unilever are among those searching for alternatives to plastics from fossil fuel polymers.

Supply chain priority

“The typical consumer company’s supply chain creates far greater social and environmental costs than its own operations, accounting for more than 80 percent of greenhouse-gas emissions and more than 90 percent of the impact on air, land, water, biodiversity, and geological resources,” McKinsey says. “Most of the environmental impact associated with the consumer sector is embedded in supply chains.”

Ethical Corp. estimates that there are about 400 sustainability labels, including Fairtrade, which got its start in 1992 but is being overtaken by alternatives. Sainsbury’s, the UK supermarket chain, is among those that have shifted from the third-party Fairtrade certification, creating its own “Fairly Traded” label.

Unilever and Nike are recognized leaders on environmental and social initiatives. Campbell Soup works with farmers to optimize fertilizer use and improve soil conservation. Walmart gives suppliers incentives for their sustainability performance. Alarmed by oceanic pollution, Nestle, Procter & Gamble, Coca-Cola and Unilever are among those searching for alternatives to plastics from fossil fuel polymers. Target, Keurig and others are pushing suppliers of industrial plastic items such as crates and trash bins to use more “post-consumer” material.

Worker rights

The safeguarding of worker rights and improvement in working conditions is often the most difficult issue on the sustainability agenda.

Five years after the Rana Plaza factory collapse that killed 1,100 garment industry workers in Bangladesh, independent assessments report improvement in factory safety and monitoring by the government and local companies. But two organizations representing western brands and retailers recently said local authorities still aren’t prepared to assume responsibility for policing safety standards.

Worker rights can be a contentious issue even for global leaders such as Nike, which developed many of the best practices now used by apparel brands and manufacturers. Nike has voiced objections to advocacy groups positioning themselves as third-party auditors, arguing that there is a conflict of interest for groups that are both campaigning and auditing. For their part, advocacy groups say many audits go too easy on brands and manufacturers.

But failure to tackle environmental and social risks can have punishing consequences. Apparel companies that contracted with Rana Plaza garment makers fell from lists of most-reputable companies in the aftermath of the tragedy. Aussie GrainCorp reported that drought cut its grain deliveries by 23 percent and led to a 64 percent drop in 2014 profits. Unilever estimated that it loses 300 million euros a year as worsening water scarcity and declining agricultural productivity contribute to higher food costs.

It is through experimentation and innovation, not spreadsheet projections, that viable sustainable business models emerge.

The business case for sustainability

Forum for the Future, an international sustainability nonprofit, says the companies set to benefit are those that can “capture the less tangible benefits as well as direct financial savings, for example, the clear reputational benefits of the initiative.”

The business-case numbers “are much ‘softer’ than decision-makers are used to,” the Forum says. As a result, “companies get stuck in a vicious cycle: they want a business case before giving permission to go-ahead with a project, but the information to build a business case can only be generated from the experience of going ahead.”

George Mason University professor Gregory Unruh says it’s time to look at the business case for sustainability a bit differently. “Multi-dimensional sustainability value is just hard to fit into a discounted cashflow analysis,” he writes.

Despite being hard to measure, Unruh writes, “investors are now realizing that sustainability performance feeds the long-term bottom line. And that’s causing managers to question traditional business thinking. So instead of spending time building a perfect business case, many are pursuing business model innovation experimentation, taking a page from Silicon Valley start-ups. It is through experimentation and innovation, not spreadsheet projections, that viable sustainable business models emerge.”

Best practices for sustainability in supply chain also mean tough questions for companies. Agility’s Mariam Al-Foudery lays out some key areas for consideration.

Best practices for sustainability are evolving as rapidly as any aspect of business, driven by new technology and an urgency for companies to demonstrate that they are effective environmental stewards and positive contributors to society.

Here are some key areas where logistics providers and their customers need to focus.

-

Traceability

Do you have upstream supplier visibility? Do you do supplier assessments and benchmarking? -

Labor

If migrant workers are in your employee mix, are you certain that they aren’t being exploited by labor brokers and unscrupulous recruiters, a problem that is particularly problematic for companies that hire from India, Nepal and East Africa?

Have you continued to focus on living and working conditions? Are you confident you have transparency into subcontractors? Have you created effective worker-grievance mechanisms? Are you educating and training workers on their rights? -

Energy

When you expand your truck fleet, are you adding CNG fueling stations and LNG vehicles? -

Packaging

If you are a consumer company, what about dimensional weight pricing? -

Warehousing

Have you looked at automation and cleantech in cargo handling and warehousing? -

Port selection

Are you routing shipments through “green terminals” that manage and contain possible pollutants and police for invasive species? -

Logistics digitization

Agility is among those using advanced algorithms to evaluate multiple scenarios and create optimal plans with the least environmental impact. Multi-echelon Inventory Optimization is another tool available. -

Data and measurement

Are you capturing, sharing and analyzing data with your logistics provider so you can get real-time feedback to optimize operations and make sure you are conserving, recycling, recovering and reusing as much as you can?

The United Nations calls modern slavery – human trafficking, child labor and debt labor – the world’s second-largest criminal industry.

Efforts to monitor and crack down on modern slavery have forced companies worldwide to scrutinize their supply chains.

The most widely known attempt to mandate corporate transparency is the United Kingdom’s Modern Slavery Act of 2015. As a result of annual reporting by companies, the UK government estimates that at least 13,000 people are victims of forced labor, sexual exploitation or domestic servitude, Thomson Reuters reported recently. More than 5,000 potential victims were referred to UK authorities last year, a record number.

Worldwide, the Council on Foreign Relations estimates there are 40.3 million victims of enslaved labor and that one in four victims is a child. The Modern Slavery Act “has done a lot to raise awareness,” Kate Roberts, head of office at the Human Trafficking Foundation, told Thomson Reuters. “Unfortunately, in practice, we’re still waiting to really see many tangible outcomes from it yet.” The Business and Human Rights Resources Centre notes similar “lagging” efforts in FTSE 100 firms with operations in the UK.

How it works

-

Who reports:

Any organization that conducts business in the UK and has an annual profit of £36 million ($50.1 million) must issue a statement within six months of the financial year’s end detailing how it has audited the supply chain and operations for slavery risks and violations.

-

What to report:

There is no template for the report, but it should be concise, written in English, approved by the organization’s board of directors; signed by the director or equivalent, and published on the organization’s public website, linked to from the homepage. UK subsidiaries, UK branches and global organizations with a significant presence in the UK (including offices, assets, clients and trade relationships) are also beholden to this obligation, a Harvard Law School forum on corporate governance and financial regulation suggests.

-

How often to report:

Annually. Each year’s report should show improvement in corporate transparency – meaning that the organization’s workforce is being educated about modern slavery, policies are being created to prevent slavery or protect those who fall within a risk category (seasonal workers, unskilled laborers and those who work in potentially dangerous environments), and resources such as budget and staff are being allocated to address risks within the organization.

-

Failing to report:

The consequences include an injunction from courts to comply, and possibly a fine.

-

Accountability:

The Modern Slavery Registry (modernslaveryregistry.org) keeps track of all published reports across 27 sectors, ranging from capital goods and consumer services to pharmaceuticals. This website also measures organizations’ compliance with the Modern Slavery Act; as of April 2018, only 19 percent met all minimum requirements.

Businesses are greening their warehouses to lower costs and reduce resource in pursuit of zero-net energy (ZNE) even without the pressure of government regulations.

A 2010 mandate in Europe is pushing companies there to achieve ZNE status for commercial buildings by 2020. To be ZNE, buildings must create onsite energy equivalent to the amount of energy they use. In the Middle East, Asia and Africa, where most of Agility’s warehouses are located, ZNE is still a distant objective. Michel Saab, CEO of Agility Logistics Parks, Operations, says the two most expensive warehousing costs are lighting and air conditioning. Ed Klimek of KSS Architects notes that lighting accounts for nearly 30 percent of the energy use within a distribution center.

Finding a sustainable solution for lighting is easier than solving the problem of exorbitant airconditioning costs. “Most of what can be done is already done at Agility,” Saab says. Skylights that provide natural light are an option for warehouses where temperature-controlled goods aren’t stored. At Agility warehouses, LED lights have replaced typical incandescent and fluorescent bulbs. Energy Star estimates that LED lights are 90 percent more efficient than incandescent lights. Another cost-savings measure is to connect lighting to a motion-sensor system that will turn off lights automatically in unoccupied spaces.

Agility has the capability to operate a similar system by customer request, but there are technical constraints in spaces where light fixtures are embedded in 14- to 16-meter high ceilings. Air conditioning is expensive and drains a lot of energy, especially in the Middle East. “Agility is looking for new air conditioning solutions, and it is a priority because of the extreme heat,” Saab says. It’s too early to say there’s a direct, viable alternative to conventional air conditioning, but Agility is finding green workarounds. Warehouses can be oriented to avoid direct sunlight and maintain low thermal heating, and UV-blocking skylights can be installed to reduce heat up to 85 percent. What’s more, water-cooled chillers can be used instead of air-cooled chillers to reduce electric demand. Simply defined, a “sustainable warehouse” is one that makes little impact on the surrounding environment (including land, water sources and wildlife), draws modestly from external power sources and is a comfortable environment for employees to work in. Though typically located on the fringes of communities – closer to air and seaports or major trucking thoroughfares – warehouses can have a major effect on a community.

They generate jobs, but they can also draw significantly from the power grid and contribute to pollution. Adopting sustainable practices within a warehouse not only benefits the community, but also makes the warehouse less expensive to operate over time. A warehouse generating its own power is also more stable; it’s not subject to power grid interruptions that compromise security systems or cold storage systems for special products. For its part, Agility is making strides toward ZNE.

“We’re working toward putting photovoltaic panels on warehouse roofs to generate our own power and electricity,” Saab says. Any effort toward environmental sustainability must be sustainable for the business as well, and that’s the current challenge. “We measure our energy consumption to pay the bills,” Saab says. But in the future, Agility can analyze those measurements to identify areas where energy use could be reduced – or even produced on warehouse premises.

Agility’s fair labor program in the Middle East was a groundbreaking initiative more than 10 years ago and has helped drive worker protections worldwide.

More than a decade ago, Agility began taking aggressive steps to protect the rights of drivers, warehouse employees and other workers who migrated in order to get jobs.

Agility is the largest logistics company in the Middle East, an area where third-country nationals have historically been vulnerable to exploitation by recruiters and to abuses on the job.

Fair labor in the supply chain

While international agencies have moved to promote fair labor practices and supply chain transparency, often after prodding by non-governmental watchdog groups, Agility has been at the forefront of efforts to ensure worker protections and call on other businesses in the region to do the same.

Agility’s initiative for fair labor

One of Agility’s first steps was ensuring a basic living wage for migrant workers. Agility also implemented procedures to prevent common labor abuses, like confiscation of passports, withholding of pay and travel restrictions. Agility’s approach to identifying and correcting fair labor practices has been in use since 2009. Since 2011, Agility has been training all levels classes of employees about those standards.

Agility’s commitment to fair labor goes all the way to the top. The company’s fair labor program is sponsored by Agility CEO Tarek Sultan, who receives regular updates on its progress from the Corporate Social Responsibility (CSR) team. “Agility is committed to providing an environment where employees’ human rights are both respected and protected. We have high standards on fair labor; it’s an essential part of the ‘Agility Way’ of doing business,” Sultan said.

The fair labor program

Agility created its fair labor program voluntarily – not in response to government or customer mandates – because the company believes in protecting its employees and contract workers. Agility isn’t winning business because it has a toptier fair labor program, but it could certainly lose business if those standards slipped, says Frank Clary, Agility’s CSR director.

Clary says the program is both a moral and legal imperative, and a company’s success in resolving fair labor issues hinges on its ability to discover them – and speak openly about correcting them.

Agility’s practices are evolving to ensure that all possible violations come to light. Agility rigorously enforces the fair labor policy with comprehensive monitoring and audits conducted by third parties. Geographic areas where the Agility workforce includes the most vulnerable population – migrant workers – get audited most frequently. The audit process includes random employee and vendor interviews, and tours of workspaces and housing. When any issue is identified, Agility prescribes corrective actions and issues timelines for achieving appropriate standards. In the case of critical issues, corrective actions are taken immediately. Customers requesting audits get the results directly.

The first phase of the Agility audit program was conducted in the Middle East, followed by roll-outs in Asia- Pacific. Ten years ago, when these audits began, many violations were discovered. Now, thanks to training programs, they have decreased.

Agility’s goal is to educate 100 percent of its workforce about the fair labor policy. The program has been conducted historically with on-site training sessions. The company is creating an online training program to reach a wider audience. There are two versions of the online program: a version designed to help employees understand their rights and learn how to report concerns, and a separate, more robust program directed at Human Resources professionals who will need to investigate those concerns.

Agility plans to share these training resources with other companies. “We want to engage to help the broader business community succeed in managing these issues,” Clary says.

Fair Labor preservation and safekeeping

There’s no quick solution to manage fair labor issues on a global scale, but every step forward helps. The Council on Foreign Relations (CFR) estimates there are 40.3 million people currently enslaved in the world, and the problem is most prevalent in “impoverished countries and [in] those with vulnerable minority communities.” Modern slavery exists primarily for financial reasons: it’s an economic crime, according to Kevin Bales, a professor of contemporary slavery at University of Nottingham in the UK. The International Labour Organization says that slavery generates $150 billion for traffickers annually. Even if companies have procedures in place to protect their workforce, how can they safeguard against unethical subcontractors who prioritize financial gain about fair labor?

Agility has taken a leadership role on the issue when it works with multinationals and government organizations in the Middle East. Working with Human Rights Watch, Agility learned how to engage engineering and construction companies in ways that prevent labor issues. The approach involves setting expectations upfront, writing contracts more carefully to demand fair labor standards, and insisting that subcontractors to open up for audits. Agility also has worked on fair labor with the World Economic Forum and Business for Social Responsibility, which has given Agility a platform to talk about the importance of the issue with others in the logistics industry.