By Tarek Sultan

Vice Chairman, Agility

There can’t be a time in human memory when travel, shipping, trade and commerce have been jolted as badly by severe weather and extreme climate events as in recent months.

In China this past summer, scorching heat forced power cuts and factory shutdowns. Apple, Foxconn, Toyota, Volkswagen, Tesla and others suspended operations, cancelled orders or took other emergency measures.

Low water on the Rhine River crippled German barge shipments as Europe experienced its worst drought in 500 years. In the United States, water levels fell so low along the Mississippi River and tributaries that farmers and others were left without routes to market for agricultural and industrial goods as barges were grounded, blocked and delayed. Dry weather and snarled transport are expected to push U.S. wheat exports to their lowest levels in 50 years.

Punishing climate-related events contributed to India’s decision to ban rice exports and caused the destruction of much of Spain’s olive crop. Historic floods left 7 million people homeless in Pakistan and displaced 1.4 million in Nigeria overnight.

“Climate change and the extreme weather it spawns are making it harder for tangled supply chains to sync up with a slowing global economy,” Bloomberg says.

At some point, post-COVID supply chains may come back into some sort of equilibrium, but don’t expect an end to ruinous climate events. This past summer was the second-warmest on record for the Northern Hemisphere. The world has not experienced a cooler-than-average year, compared with the 20th century average, since 1976.

Axios reports that a climate migration has begun. It says a number of manufacturers, hospitals, airlines and other businesses are looking to put critical infrastructure and operations on higher ground to avoid coastal flooding and storms.

“Companies large and small, some with longtime roots in their neighborhoods, are on the hunt for new real estate that is less prone to weather and climate extremes,” Axios says.

Skeptics, of course, are vocal as ever. Some warn that climate policy is the real threat. “Anyone who still thinks climate change is a greater threat than climate policy to financial stability deserves to be exiled to a peat-burning yurt in the wilderness,” one wrote recently.

Hardly. Instead, it would be foolish not to be giving serious scrutiny to your business and any vulnerability it might have to climate extremes. Some questions to ask as you do:

1. Do you need to “harden” buildings and infrastructure?

Do you need a new home for essential operations in order to safeguard against flooding, high winds, catastrophic storms, rising sea levels or drought-driven fires?

2. Are you too water-dependent?

Do you rely too much on hydropower or on inland river transportation? What’s your backup?

3. Are extreme high temperatures putting employees at risk?

How are you safeguarding them? What about your vehicles, equipment, raw materials and finished products?

4. How well do you truly understand your supply chain?

Have you mapped your T1, T2 and T3 suppliers? Do you know where they get their inputs? How vulnerable are your sourcing and transport? Do you have built-in redundancy?

5. Do you have a handle on carbon taxes?

Do you know where you might face the prospect of higher taxes simply by moving the same goods across the same borders? Or where carbon taxes could come into play when you are sourcing from and selling into new markets?

6. What if you have to move?

Can you afford to shift locations of key operations? Do you have a new location in mind? Can you find the right employees there? What kind of reputational damage would you face if you left or shrunk your footprint in a community where you have roots?

7. What’s your plan if suppliers or carriers negate agreements through force majeure?

Finally, are you committed to change? Are you all-in on the battle to reduce emissions and work toward a safer, cleaner, greener world?

By Tarek Sultan

Vice Chairman, Agility

The past two years have delivered a steady stream of bad news about our fragile planet, income inequality, vaccine inequity and a host of other problems that seem intractable.

The daily doom and gloom about climate change, job losses and lack of access to COVID vaccines feeds our sense of anxiety, vulnerability and helplessness. I think it also clouds our ability to see that we are living in an era of breathtaking human innovation and heroic problem solving.

A few potential game changers that have caught my eye:

-

“Green” steel and CO2-enriched concrete

Several companies, including H2 Green Steel and Hybrit of Sweden, have begun using hydrogen and non-fossil fuels to produce “green” steel. That’s important because steel is one of the world’s most widely used materials, essential in construction, fabrication and consumer goods, and is normally made through a carbon-heavy coking process that uses coal. In conventional steelmaking, nearly two tons of CO2 are emitted for every ton of steel produced. That’s about 7% of global greenhouse emissions.

People tend to think of hydrogen as an answer for transportation emissions, says Sunfire CEO Nils Aldag. Instead, it might be a better power source for “hard-to-abate” sectors like the chemical and steel industries, he says.

Production of concrete and cement is just as concerning. Depending on how it’s measured, concrete production is responsible for 4% to 8% of man-made carbon emissions – more than any country except for China and the U.S. on an annual basis. To make concrete you need stone and sand, then cement to bind it by adding water. To make cement, you need to kiln-fire a mix of materials in a dirty process that releases a lot of CO2.

But it turns out that CO2, captured from industrial processes, can be injected into concrete during the curing process to strengthen it. Canada’s Carbicrete and the U.S. company Solidia are doing just that. Zero-carbon concrete is coming — the question is when, experts say.

-

-

COVID vaccine factory-in-a-box

-

BioNTech partnered with Pfizer to develop and scale the West’s first COVID-19 vaccine. Now BioNTech says it can solve the worrisome problem of scarce vaccine supplies in Africa with mobile, modular production units that could each manufacture up to 50 million doses a year.

Individual vaccine production units are comprised of 12 shipping containers, which can be moved by air, sea, road or rail and can also be used to make vaccines to ward off malaria, tuberculosis and other diseases. Even more impressive: BioNTech pledges to cover the cost of development, manufacturing and shipment.

-

Eliminating food waste and feeding the hungry

By some estimates, up to 40% of food in the United States is thrown out. And in Africa, half or more of perishable food commodities go bad before they reach the market or table. What’s more, food waste contributes about 8% of global greenhouse gas emissions.

Goodr, a startup company, has developed software that tracks surplus food, helps customers such as restaurants, airports, schools, hospitals and grocers cut down on the amount they waste and donate what might otherwise go in the garbage. Goodr automatically generates tax donation receipts so customers can write off what they give away.

-

A bio-materials revolution

Consumers want more sustainable products, and regulators are mandating lower emissions. So product makers are turning to DNA sequencing, gene editing and AI to make bio-materials and processes that can substitute for plastics, foams, synthetic fabrics, elastomers and other materials made from petrochemicals and processing chemicals.

With automation and high-powered computing, they are able to effectively “engineer” biology and produce physical materials that perform better and are more sustainable. The result is a coming bio-materials revolution that will change what goes into our clothes, cars, electronics and consumer goods, as well as the packaging they come in. We’ve already seen the first wave in lab-grown meat, plant-based clothing, plastic substitutes, and fabrics made through fermentation.

-

Eliminating supply chain blind spots & helping small business

Sourcemap promises shippers something they haven’t yet found: 100% traceable, transparent supply chains. Its software helps companies create end-to-end mapping for due diligence, customs compliance, environmental and social sustainability, business continuity, operations planning and other uses.

“Identify the suppliers you didn’t know you had,” Sourcemap tells customers.

SME Climate Hub gives small businesses carbon calculation tools to help them measure, lower and report emissions. The tools allow smaller businesses to take climate action and meet the growing demands from customers and consumers for data, reporting and progress on CO2 emissions.

SME360, backed by the International Chamber of Commerce, is another initiative that gives smaller businesses the tools they need to measure and track their impact on the environment.

-

Cleaner ocean shipping

The Yara Birkeland, the world’s first autonomous, emissions-free containership, made its maiden voyage in late 2021. The battery-powered ship will be used to transport fertilizer in Norway, handling loads now made with 40,000 diesel-truck trips each year.

The ocean industry is also looking at methanol and ammonia, two cleaner-burning fuels that are expensive to make and hard to obtain in sufficient quantities. Maersk, the world’s largest ocean carrier, says it is working with partners in Denmark to scale production of methanol, a carbon-neutral fuel, starting in 2023. Maersk has ordered 12 methanol-powered liners, at a cost of $175 million a ship, that can each carry 16,000 TEUs.

On the software side, Searoutes is one of many companies helping shippers build custom routing algorithms and data sets to lower shipping emissions.

-

On the road

Lithium batteries are the key to electrification of cars and trucks, but they pose their own problems. One concern is that there is a limited known supply of lithium, concentrated mainly in Australia, Chile and China. Warren Buffett’s Berkshire Hathaway is among those looking for lithium in new places. It has discovered vast deposits in a California lakebed.

A related problem is the lack of charging infrastructure for electrified vehicles. Daimler, Black Rock and NextEra have joined to build a nationwide charging network in the United States for medium- and heavy-duty battery electric vehicles and hydrogen fuel cell vehicles.

Companies like Hyliion, a U.S. company developing low-emission and zero-emission power train systems for heavy trucks, have drawn a lot of attention from investors and the general public. Less noticed have been innovations in niche transportation areas. Frigoblock and Thermo King, for example, have pioneered emissions-lowering electric systems for refrigerated trucks that are used to ship perishable foods, medicines and other cold chain products. Now, they are working to make those vehicles noiseless so that they can be used for off-hours deliveries in congested urban areas. Volta Trucks is another company pioneering sustainable urban trucking.

-

Shortening supply chains

3D printing or additive manufacturing has been a tantalizing – but extremely limited — technology since it was first developed in the 1980s. Beyond certain specialized uses, it’s been hard to scale or to use for high-end products with lots of components.

Seurat Technologies has figured out a way to speed up and scale 3D manufacturing and use it to make sophisticated products and parts containing metal. Seurat’s breakthrough involves a technique that splits a laser into many beams that are programmed to do their own printing.

One of the benefits of 3D printing is that it shortens supply chains by moving production closer to end users and eliminating the need to transport goods long distances.

-

The grid

The clean power conundrum is really three problems: generation, transmission and distribution. Renewables such as wind and solar, along with cleaner-burning fossil fuels, offer an answer as to how we will generate power with little or no emissions. But there can be no net-zero power grid without long-duration energy storage (LDES) that addresses the problems inherent in trying to store energy while making transmission and distribution cleaner and reliable.

The problem of long-term storage for the grid has spawned an industry devoted to using new and existing technologies – mechanical, thermal, electrochemical and chemical – to store energy from different sources and release it efficiently to correspond with demand.

-

Chance to make a difference

Individual investors suddenly have lots of options to channel their retirement savings and other funds into responsible investments that are tailored to their interests.

Socially responsible investing is not new, but the variety of options is large and growing. One example: the thematic investments offered by Fidelity. They include funds comprised of companies that are developing disruptive technologies; built to capitalize on megatrends; or structured with sustainable practices, diversity and strong governance. Some of the thematic fund sectors: digital health, electric vehicles, cloud computing, and clean energy.

My point is that the momentum behind serious global problem solving is undeniable. And it is making a difference.

McKinsey says capital is “increasingly plentiful” for next-generation technologies and estimates that they could attract $1.5 trillion to $2 trillion in fresh investment annually by 2025. One indication is the creation of the First Movers Coalition, a group of global companies that includes Agility, which is pledging to help build early market demand for low-carbon goods and services.

It will take all of this and more to make our world cleaner, fairer, safer and more just. Let’s not get so caught up in the gloomy headlines that we lose heart, or fail to recognize that we’re making progress.

Mobility ecosystems are transitioning as economies recover and move to zero-emission road transport by 2030. The aim of this session is to enhance global collaboration on the path to inclusive and sustainable mobility recovery.

The economic damage and costly business disruption brought on by the global spread of the COVID-19 virus have failed to slow the gathering momentum behind environmental sustainability and the array of efforts to battle climate change.

After decades of doubt on the part of business leaders, sustainability is delivering ROI. Businesses, investors, consumers, governments and others see it as a source of post-pandemic resiliency, efficiency and competitive advantage. Why is it proving durable now?

1. A green recovery could be a stronger one

“A low-carbon recovery could not only significantly reduce emissions, but also create more jobs and economic growth than a high-carbon recovery would,” McKinsey says.

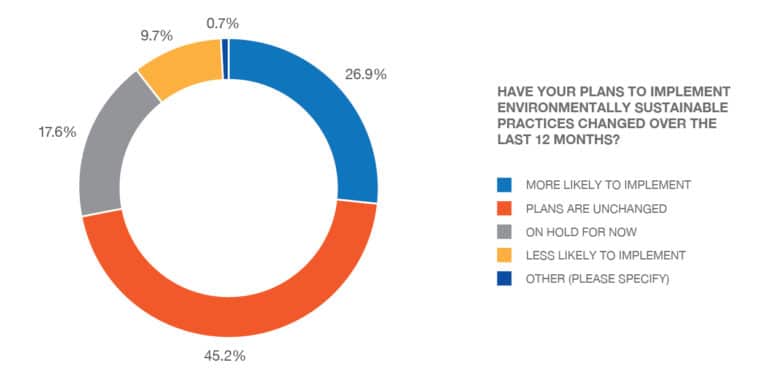

Many industries are doubling down on sustainability investments. Few are backing off. In an Agility survey of 1,200 global supply chain executives, 72% of respondents said their companies will maintain or increase their environmental sustainability commitments coming out of the pandemic.

Want more proof? In May, the International Energy Agency slashed its forecast for the amount of renewable energy capacity to be added worldwide in 2020. But by year’s end, the IEA was forced to backtrack.

“The renewables industry has adapted quickly to the challenges of the COVID crisis. We have revised the IEA forecast for global renewable capacity additions in 2020 upwards by 18% from our previous update in May. Supply chain disruptions and construction delays slowed the progress of renewable energy projects in the first six months of 2020. However, construction of plants and manufacturing activity ramped up again quickly, and logistical challenges have been mostly resolved with the easing of cross-border restrictions since mid-May,” the IEA says.

2. Investors want more

Global asset managers want in on sustainability. In 2020, they poured more than $5 billion into so-called blank-check companies created to invest in businesses that are driven by environmental, social or governance (ESG) principles or formed to bring ESG ideas to market.

“Capital markets are wide open for investment in green businesses in a way that they’ve never been before: Interest rates are at historical lows, technology costs have fallen, and financial regulators are beginning to nudge investors, so the risk-reward equation is beginning to shift,” says Dickon Pinner, who leads McKinsey’s global Sustainability practice.

There were 20 ESG-focused blank-check companies — also known as Special Purpose Acquisition Companies (SPACs) – launched last year, according to Pitchbook. (Agility said in January that it invested $35 million in Queen’s Gambit Growth Capital, a blank-check company that will target businesses offering sustainable solutions in clean energy, healthcare, financial technology, industrials, mobility and emerging technology.)

3. It’s a culture thing now

A report by SAP and media firm Which-50 indicated a “strong shift to sustainability” among the corporations tracked by consultants and research firms such as BCG, Gartner, Juniper and Forrester.

“Sustainability has shifted from a discussion largely driven by compliance to one at the centre of business strategy,” says Which-50.

Companies are taking aggressive steps to stay ahead of the pack. VF Corp., parent of Timberland, North Face and Vans brands, is one of many companies drilling deeper into their own supply chains. VF’s traceability mapping gives the company a view of its tier 1 through tier 4 suppliers. In a show of transparency, VF has posted 46 of 100 anticipated product maps online.

4. Businesses can’t afford to be out of step with consumers

In a recent survey of European consumers, 57% of respondents said they had made significant changes to their lifestyles to ease the environmental impact. More than 60% said they were taking steps to recycle and buy products in environmentally friendly packaging.

“Consumer behavior and changing tastes are all moving in the direction of sustainability and adding pressure on companies and brands to do the same,” says Mohammed Esa, Agility GIL’s Senior Vice President of Global Business Development. “Social media plays a big role because it gives consumers a much bigger voice than they ever had.”

5. There is competition … and cooperation

Thousands of companies have announced ambitious goals. Apple, for instance, vows to be carbon-neutral by 2030.

Fifty-three companies signed the Climate Pledge, co-founded by Amazon, committing to getting themselves to net-zero carbon emissions by 2050 – 10 years ahead of the Paris Agreement. The pledge requires them to adopt rigorous reporting, cut emissions and neutralize remaining emissions with credible offsets. Climate Pledge signatories include Microsoft, IBM, Johnson Controls, Unilever, Canary Wharf Group, Uber, Henkel, Siemens, Mercedes-Benz, Infosys, Real Betis, Daabon Group,

Another group has promised to share best practices for achieving net-zero emissions. The Transform to Net Zero initiative includes Maersk, Danone, Mercedes-Benz, Microsoft, Natura & Co., Nike, Starbucks, Unilever, and Wipro. The initiative makes business plans and other resources available online.

6. Technology is making it easier

TextileGenesis, based in Hong Kong and India, is one of many apparel companies adopting blockchain so it can track the sourcing of raw materials through to production and shipment of finished garments.

The fashion and apparel industry is moving to introduce sustainable materials such as recycled cotton, lyocell (made from wood pulp) and viscose (made from wood) in place of less environmentally friendly fibers like polyester and nylon, which contain petroleum, coal and chemicals. Blockchain would help apparel manufacturers source, track and certify their use of the new materials.

Piramal Glass, an Indian company that makes bottles and glass packaging for the pharma, cosmetics and perfume industries, is using blockchain to get supply chain transparency and auditability.

Another important advance is the use of digital or virtual twinning.

The flood of data available from the Internet of Things (IoT) and cloud computing makes it possible and cost effective to create digital “twins” that model and simulate processes with potential to deliver environmental benefits.

“This pairing of the virtual and physical worlds allows analysis of data and monitoring of systems to head off problems before they even occur, prevent downtime, develop new opportunities and even plan for the future by using simulations,” says Forbes.

The Port of Rotterdam is using digital twinning to model automation, design and sustainability features that are part of its push to become “the world’s smartest port.” Twinning gives port planners the ability to virtually test use of autonomous ships, “digital handshakes” for documentation exchanged between vessels and the port, and emissions-lowering port call practices.

Without digital twinning, port officials would have no way to test the transformational processes without disrupting operations at a sprawling port that handles 8.8 million containers and 15 million twenty-foot equivalent units a year.

“In a virtual environment, we can verify and validate solutions before the real tests begin, maturing solutions much faster. We also don’t have the safety risks or hazards we would in real-life tests and that’s why this digital environment is better and faster for development and validation work,” says Karno Tenovuo, CEO of Awake.AI, the Finnish company that is Rotterdam’s smart-port development partner.

Tenovuo says ports will able to lower CO2 emissions 10% by adopting the features and optimization methods that will be harnessed in Rotterdam.

7. The ocean industry is racing to catch up

Slow to embrace sustainability, the maritime logistics industry is now an area to watch.

Leading container lines and ports are working on standards for a just-in-time port call process that would eliminate wasteful delays and dwell times. JIT port calls would allow ships to optimize steaming speed, lower fuel use, cut CO2 emissions, and avoid getting stranded outside ports waiting for berthing slots.

Singapore’s futuristic Tuas port is being built to handle 65 million TEUs a year. By consolidating existing container-handling facilities at a single location, Singapore will cut inter-terminal trucking hauls and emissions. Reused and recycled materials make up half of the land reclamation work, and the port is moving sensitive coral colonies that would have been damaged by the construction.

Maersk, the world’s largest container line, is accelerating development and deployment of the world’s first carbon-neutral container ship. Maersk says the vessel, a smaller ship known as a feeder, will run on biomethanol, made from paper-mill waste and other byproducts. It will join the Maersk fleet in 2023.

RightShip, a maritime risk-management company, created a ratings system to compare the efficiency of different cargo ships, along with operational performance used to score ships on safety. RightShip ratings allow shippers to choose vessels with lower CO2 footprints, better fuel efficiency, and higher safety ratings.

8. There are carrots to go with sticks

European Union companies that rely on imports from South Asia are promising broader market access, training and gap assessments for Sri Lankan exporters whose products can meet international sustainability standards.

The initial group of Sri Lankan companies are providers of rubber, apparel and food products, but a German and EU business delegation has agreed to help Sri Lanka extend the project to its critical tourism sector.

Banks and venture capital firms are offering preferential terms to companies that agree to meet environmental criteria, such as reporting CO2 emissions and implementing emissions-reduction strategies.

9. The sticks are real

In early 2020, BlackRock, the world’s largest asset manager, notified hundreds of listed companies in its portfolio that it had started to factor environmental issues and performance into its investment decisions.

A year later, BlackRock told its own investors that it had voted against the management of 53 companies – including some of the biggest global names in manufacturing and industrial supply – because those companies failed to “make sufficient progress regarding climate risk disclosure or management.”

Too many companies still rely strictly on internal data to get a picture of their supply chains. To strengthen their post-pandemic supply chains and drive sustainability, many realize they need to exchange data with suppliers and customers.

10. There’s nowhere to hide

Seventy-percent of shippers look at sustainability as part of RFPs, and more are requiring their vendors to report on sustainability metrics on a regular basis. They want to know about fuel efficiency; CO2 emissions; alternative fuel use; personnel & staffing devoted to sustainability; and fleet age.

Climate TRACE, an alliance of climate research groups, is close to launch of an initiative that will track and publish greenhouse gas emissions traceable to individual factories and ships.

“Our work will be extremely granular in focus – down to specific power plants, ships, factories, and more. Our goal is to actively track and verify all significant human-caused GHG emissions worldwide with unprecedented levels of detail and speed,” the alliance founders say.

Climate TRACE will give business leaders, investors, NGOs and climate activists a powerful tool “while ensuring that no one – corporation, country, or otherwise – will ever again have the ability to hide or fake their emissions data.”

Businesses that regularly transport goods often ask an important question: What is green distribution, and is it a feasible way to reduce the impact on our planet? Green distribution refers to logistics practices that minimize environmental harm. It is possible to make greener choices across the supply chain, including storage, order processing, packaging, and final-mile delivery. Green logistics reduce waste and emissions—ideal for businesses that hope to shrink their carbon footprint.

Green distribution is just one solution for a growing problem, but it stands to make a big difference. The European Commission reports that maritime transport alone is responsible for about 2.5 percent of global greenhouse gas emissions. The Environmental and Energy Study Institute found that commercial aviation is responsible for about 5 percent of global warming. And the US Environmental Protection Agency reports that containers and packaging comprised 82.2 million tons of municipal solid waste—28.1 percent of all municipal waste produced in the U.S. in 2018. In short, the impact of logistics activities can add up. At Agility, we believe it’s in our collective best interest to do our part for a greener world. That’s why we’re committed to building greener supply chains and educating our clients about how they can ship goods both sustainably and efficiently.

Importance of sustainable distribution methods

Sustainable distribution methods reduce carbon dioxide (CO2), a greenhouse gas causing global warming. These practices also reduce waste and optimize resources to improve the health of our planet and build a better future. And they help businesses take action to make changes that matter to them and their customers.

How does distribution impact your ecological footprint?

Distribution consists of many activities, from packaging to transportation, that have a substantial impact on the earth. One way to think of this is in terms of your organization’s ecological footprint. This term refers to how much of the biological capacity of the planet your business needs in order to operate. Calculating this accurately is far from simple since you must take into consideration everything from the urban infrastructure and roads you rely on for distribution to the waste products and CO2 emissions you produce.

Virtually all businesses contribute to what’s known as ecological overshoot. This is when our collective demand on the Earth’s ecosystem exceeds its ability to absorb our carbon dioxide emissions and regenerate the resources we have used at a rate that keeps pace with our consumption. That’s disheartening, but there’s a lot we can do to reduce overshoot. Even actions as simple as recycling can shrink a company’s ecological footprint. And adopting green distribution methods can make a big difference, especially over a long period.

5 benefits of sustainable distribution methods

Hands down, supply chain sustainability is better for the planet. But businesses can achieve many other benefits from striving for sustainability:

-

Increased efficiency

Green distribution practices prioritize efficiency to prevent wasted energy. That could mean anything from packing trucks or shipping containers more efficiently to achieving optimal fuel efficiency during ground transportation. Sometimes, it even comes down to how seamlessly your team works together to get the job done, which could mean less idling equipment. All of that adds up to significant energy savings and reduced carbon emissions. But what’s more, a business that runs smoothly tends to have a happier team, better customer outcomes, and less wasted resources. Since improving operational efficiency tends to be a goal for most businesses, think of this as a win-win for you and the environment. -

Reduced costs

Needless to say, reducing energy use is better for your bottom line. Even relatively small changes, like remembering to turn off outdoor floodlights during the day, could lead to big savings for your operation. For instance, a 2018 energy audit conducted by researchers found that a Zimbabwean industrial site could achieve annual electricity cost savings of over $50,000 per year simply by improving its lighting technologies. And when one of our customers wanted to decrease supply chain waste by reusing cartons, Agility collaborated with them to double carton reuse and save $128,000 over a period of five years. When you consider that sustainable distribution streamlines many functions across your supply chain, it’s easy to imagine how fast the savings can add up. -

Improved risk management

Sustainable distribution methods can reduce several kinds of risk for your organization. For one, greener practices are better for the overall health of your employees and the environment surrounding your distribution centers. After all, your business can be liable for issues resulting from harmful practices—like not adhering to regulations for greenhouse gas emissions from commercial trucks. In addition, organizations face risk to their reputations. Customers value environmentally responsible businesses. Irresponsible behavior such as excessive waste generation or failure to take environmentally beneficial actions can ultimately harm your brand. -

Improved service

Increasing your organization’s efficiency doesn’t just achieve green gains. It leads to satisfied customers. For instance, by streamlining your operations to reduce energy use, you could achieve cost savings and pass them on to consumers. Perhaps more importantly, today’s customers care about making sustainable choices. According to a recent study by Barron’s, two-thirds of North American consumers say they prefer eco-friendly brands. Changes such as switching to recyclable, biodegradable packaging material can help your customers feel better about their purchasing decisions, making them more likely to shop with you again. -

A competitive edge

Making the effort to go green can lead to a competitive advantage across many areas of your organization—from employee recruitment and retention to positive online reviews. Why? Because green business practices are better for workers, communities, and the planet. Doing your part to protect the environment, such as saving water, switching to renewable energy, and using recycled materials ensures your organization can continue operating sustainably and profitably in the future. If your competitors aren’t doing the same, they’ll struggle to adapt to the values and regulations of the changing business landscape. Finally, committing to sustainable distribution practices is key to keeping your organization top of mind for environmentally conscious consumers. When it comes to communicating your values to your customers, a choice as simple as compostable packing materials speaks volumes.

Getting started with green distribution

Turning a traditional supply chain green doesn’t need to happen overnight. It all starts with breaking down your processes to see how you could make more environmentally friendly choices at every step.

Components of green distribution

Every component in the distribution process has room for improvement. Achieving truly sustainable operations means taking a close look at every leg of your customer’s and product’s journey:

-

Warehousing

Could your warehouses be greener? Most likely, yes. These buildings tend to be drafty and, in some cases, larger than they need to be. This makes them costly to heat and cool. And of course, heating and cooling processes—along with lighting and warehouse equipment—cause significant CO2 emissions. In addition, warehouse location matters. Distribution centers located few and far between means more miles of ground transportation, leading to more emissions.

Overhauling your own warehouses or rebuilding from the ground up can be prohibitive, though when constructing new distribution centers, green options abound. For instance, warehouse architecture could minimize wasted space and even maximize natural light to reduce the need for electric lights. That said, there are many ways to improve the warehouses you already have—starting by changing the way you power them. For instance, installing solar photovoltaic roof panels lets you make use of a plentiful resource in shade-free warehouse complexes: the sun. Painting your roof a reflective color can help keep your warehouse cooler and reduce the cost of air conditioning. And hydro and wind power offer alternative energy sources that can replace or minimize your reliance on fossil fuels. These changes can make a big difference in your carbon footprint, not to mention your operational expenses.

Do you rely on a third party for warehousing? In this case, location is everything. Ideally, choose a warehousing partner with many locations around the country. Having distribution centers convenient to major shipping ports, airports, and urban centers with a high concentration of your customers can help you maximize ground transportation efficiency. -

Packaging

Unsustainable packaging doesn’t just lead to more waste in landfills. It causes environmental impact at every phase of its life cycle, from material sourcing to transportation to disposal. Packing peanuts made of Polystyrene foam are especially notorious. They aren’t biodegradable and cause harm to fish and wildlife who eat them. In addition, producing packing materials often uses nonrenewable resources, like plastic. NPR reports that emissions from producing and incinerating plastics could amount to fifty-six gigatons of carbon between 2019 and 2050.Fortunately, there are many alternatives on the market. For starters, shippers can choose from packaging materials made from recycled materials, including corrugated cardboard “bubble wrap.” Air pillows are another sustainable packaging idea. Since they’re mostly air, they minimize the material needed to make them but keep products safe during shipping. And lately, many biodegradable packaging materials have entered the market. For instance, cornstarch packaging has plastic-like properties but consists of organic materials. And mushroom packaging uses agricultural waste, so your customers can compost it in their backyards.When evaluating green packaging, consider a few factors. For one, packaging should ideally make use of renewable energy at every stage of its life cycle. That includes materials sourcing, manufacturing, transport, and disposal. In addition, optimized packaging should use renewable and recyclable materials. And finally, it should have a design that is as efficient as possible to minimize waste at every step—and optimize loads for transport too. Even a change as simple as switching from rigid to flexible packaging can increase the volume of goods that fit into a truck, reducing loads and overall emissions. -

Transportation

In most cases, transportation will be the area of your distribution operations that has the most environmental impact. Vehicles that run on gasoline and diesel emit CO2, the major culprit in environmental issues such as global warming and acid rain. Add to that the fact that fossil fuels are nonrenewable resources, and sourcing them presents an ongoing environmental threat. And ground transportation is not the only source of harmful emissions. Shipping by air and sea—a critical part of the journey for importers and exporters—causes environmental hazards too. Beyond air pollution, ships can release oil and chemicals into the sea, harming water quality and marine life. The same goes for planes, since jet fuel and other chemicals can enter waterways in the form of runoff.So what can you do? For ground transportation, you can use fleets that run on alternative fuels or even invest in electric trucks, which have improved to the point where they’re suitable for long hauls. Other green transportation methods, such as rail, offer another possibility. When shipping by air or sea, consider consolidating goods as much as possible to minimize the number of shipments you make in a given time frame. By packing more efficiently, you could ultimately reduce your carbon footprint. Finally, partner with a freight forwarder that’s committed to sustainability—like Agility. We’ll help you make the necessary changes to your supply chain to ensure a greener journey at every step.

How can existing practices become economically and sustainably refurbished?

Wondering how to develop a green distribution strategy without overhauling every aspect of your operations all at once? In many cases, some adjustments to your existing practices can make a big difference. Here are some tips to help you start transforming your distribution processes—even if it’s just a little at a time:

-

Audit your HVAC system.

Heating, ventilation, and air conditioning (HVAC) systems use a lot of energy, and they aren’t always as efficient as they could be. An HVAC technician can spot inefficiencies and fine-tune your system to save you energy. That’s good for the environment and your bottom line. -

Invest in insulation.

You’ll recoup the costs in no time. Drafty warehouses require much more energy and expense to achieve temperature control. By installing installation, you can heat or cool your warehouse more efficiently and even save wear and tear on your HVAC system. -

Keep equipment maintained.

When equipment isn’t in optimal shape, it may not perform as efficiently. Maintenance also extends the life of the product. Remember, replacing equipment before the end of its life span has an environmental impact too. But when the time is right, look for energy-efficient replacements. -

Switch to energy-efficient lighting.

Today, there are many great options on the market, like light-emitting diodes. Making the upgrade is greener and will reduce your electricity bill. -

Research new packaging options.

It can take some time to find the right packaging solution for your products, so get started now. Biodegradable materials are more eco-friendly and can even make a good impression on your customers. In addition, much of the packaging on the market today is lighter in weight, making it more efficient to ship. That can lead to reduced emissions during transport. -

Consolidate your shipments.

Do you frequently send out less-than-truckload shipments? Consider sending full truckloads, since it’s easier to efficiently pack a full truck with no wasted space. Optimal packing means fewer trucks on the road and less emissions. -

Change trucking policies.

Having clear engine shutdown policies help drivers know how long is too long when it comes to idling. It’s also important to evaluate trucker speed and provide clear guidelines for how fast they can go. That means knowing your vehicles’ optimal range and figuring out the right balance of fuel efficiency and acceptable delivery speed. These kinds of changes can make a big difference when it comes to reducing carbon emissions. -

Offset your carbon footprint.

A good start to going green is to make a donation that offsets your organization’s carbon use. Many organizations offer this service, giving you a way to make contributions to vital projects such as planting trees and restoring the rainforest. Just as importantly, it’s a way to start calculating and becoming conscious of your carbon emissions. After all, awareness is the first step to change.

Best products for green distribution

Today, businesses are fortunate to have many options for achieving green distribution. In particular, the marketplace offers a wealth of better products and packaging to replace unsustainable kinds. When looking for the best products for green distribution, consider the following criteria:

- Low emissions. Emissions don’t just apply to manufacturing and transport. Products themselves can emit volatile organic compounds and formaldehyde. Always opt for goods that promote good air quality—indoors and out.

- Choosing products and equipment built to last ultimately leads to less waste. However, when choosing material like packaging, too much unnecessary durability could actually lead to more waste. After all, your customer is only going to recycle or dispose of the materials. So invest in durability when it makes sense.

- Recycled content. Products that use postconsumer or postindustrial recycled content tend to be the greener choice.

- Reused content. In some cases, it’s possible to find salvaged or upcycled products. For example, if you’re constructing a warehouse from the ground up, consider incorporating reclaimed materials.

- Manufacturing process. How was the product made? Items made via natural or renewable resources—such as wood or corn—are more sustainable than those made from nonrenewable resources, such as petroleum. Also, make sure the manufacturing process doesn’t result in toxic by-products that could damage the environment.

- Supplier location. Products that need to be shipped long distances, or that use imported materials, require more energy throughout the supply chain. If at all possible, choose local, sustainable suppliers.

- Ozone friendliness. Look for products that don’t contain ozone-depleting substances. For example, aerosol sprays, blowing agents for foams and packing materials, refrigerants, and other substances contain chlorofluorocarbons, which can damage the ozone layer.

- Sustainable harvesting. This applies to wood or other natural products. Sustainable harvesting or sustainable agriculture uses a set of practices and principles to ensure careful resource management. For instance, instead of clear-cutting woodlands, foresters harvest trees selectively and make sure to leave plenty for the future.

- To minimize waste, choose products that are recyclable. In particular, look for materials that are suitable for a closed-loop recycling system. Closed-loop recycling is when manufacturers can turn recycled materials into the same products many times over without much loss of quality. For example, it’s possible to recycle glass and metals such as steel again and again. And to minimize waste, avoid single-use products whenever possible.

- Distributors can’t control whether customers recycle packing material. But with biodegradable materials, at least they know packaging will break down easily in a landfill. Consider that paper products can biodegrade in as little as a few months, whereas plastic bags take five hundred years or longer.

When evaluating the types of packaging most sustainable for green distribution, you need to factor in not just the above criteria but also your performance goals. After all, having your products break during transit isn’t sustainable. Fortunately, there are plenty of great options out there—from corrugated cardboard packing materials to reusable plastic shipping cartons. Your choice comes down to whether a given product’s costs, performance, and sustainability meet your organization’s objectives.

How to achieve green logistics in the transport stage

A key principle of green logistics is minimizing wasted energy and its resulting emissions. You can do that by optimizing cargo space, which helps reduce the number of trips you need to make. In addition, load-planning software takes the guesswork out of logistics planning. Since load optimization involves many factors—from vehicle capacity to load requirements and how far your goods need to travel—logistics companies such as Agility rely on this sophisticated software to plan optimal routes. Rely on us to ensure your shipment gets from point A to point B as efficiently as possible.

Latest green practices in supply chain management

Supply chain management is a constantly evolving field, with new and greener solutions arriving by the day. In part, that’s because green supply chains lead to competitiveness and economic performance. Since sustainability measures increase energy efficiency and rely on cost-efficient recycled products, they’re good for a business’s bottom line.

In fact, Boston Consulting Group found that businesses leading in environmental, social, and governance practices have an 11 percent valuation premium, compared to their competitors. What’s more, the majority of consumers say they are willing to pay a price premium for sustainable goods. As consumers clamor for greener brands, companies must compete to incorporate sustainable practices throughout the value chain. This drives green innovation in pretty much every field—including supply chain management.

How can supply chain leaders incorporate green practices while maintaining profit margins?

Today, supply chain leaders use the following methods to go green while maintaining—or growing—their profits:

-

The green service model.

These days, supply chain leaders don’t have to invest in all-new green equipment or the technology that enables logistics efficiency. They can rely on the service model instead. You can find everything from eco-friendly warehouse lighting to alternative energy sources as a service. That means you don’t have to assume the upfront expense, risk, and ongoing maintenance of green solutions. An expert service provider handles everything for a monthly fee. -

Thinking outside the box.

It’s fully possible to combine green distribution practices with the goal of increasing cost efficiency and profits. Supply chain leaders do this every day. For instance, they may discover that new, lighter packaging reduces cargo weight and volume—thereby trimming costs and energy use. Or they may determine that shipping large volumes of goods by ocean freight instead of transporting smaller quantities via air freight is both a cost saver and a more sustainable choice. Don’t be afraid to dive in with both sustainability and profitability in mind and see what creative solutions you come up with. -

The circular economy.

Traditionally, many business processes—including the supply chain—produced a lot of waste that ended up in landfills. Today, supply chain leaders are changing that by giving waste materials a new life. This method is known as the circular economy model, and its possibilities are endless. For instance, businesses could turn recycled content into green products or packaging or sell by-products instead of discarding them.

The challenges of implementing green practices in supply chain management

When trying to improve sustainability performance in the supply chain, businesses tend to struggle with the following areas:

- Since the field of sustainable supply chain management is still evolving, supply chain leaders may not know the latest facts and best practices.

- Operational changes. Yes, change can be disruptive. Implementing green initiatives may require you to reimagine ingrained practices or enforce new protocols. In time, these will become your team’s new normal.

- Finding cost-effective and sustainable materials and equipment—and establishing new supplier relationships—may require time, planning, and upfront costs.

- When implementing new measures, expect some initial resistance. Communicating the importance and efficacy of sustainable practices—and listening to your team to address snags along the way—is key to going green.

By understanding how green warehouse practices reduce cost, modern companies reap the benefits of improved bottom lines while boosting their corporate image.

Going green proves to stakeholders that a company values sustainability and cares about the larger world outside the corporate conference room. Indeed, research shows that such initiatives are vital to global health now and in the future. And with the right green warehouse practices, the benefit becomes twofold by leading to cost savings as well.

This article covers the cost-effective, competitive advantages of a green warehouse. Discover which green warehouse practices will save you the most money and how to implement them.

Gaining a cost-effective, competitive advantage through a sustainable green warehouse

Going green provides a competitive advantage, especially considering public interest in green initiatives. Suppose a prospective customer is choosing whether to buy from a company that implements sustainable practices or one that does not. A majority of studies show that all other factors being equal, consumers are more likely to choose the greener option.

Implementing green practices can also lead to cost savings because many green practices center on improving efficiency and reducing waste. Multiple supply chain leaders have achieved significant savings by adopting green practices. For example, Amazon’s data centers run entirely on renewable energy, which costs the company an estimated 10 percent less than using fossil fuel energy.

How supply chain leaders can incorporate green practices while maintaining profit margins

Now more than ever, supply chain leaders consider sustainability efforts to be critically important. In a 2017 survey by EcoVadis and the HEC Paris business school, 97 percent of procurement officers named sustainability as one of their top five priorities. In addition, 75 percent of companies in the survey reported that they took environmental sustainability and social responsibility into account when selecting new suppliers.

Agility, which builds a number of green features into its warehouses, has also invested in a number of sustainable innovation companies. One is Hyliion, which is developing an electrified powertrain system for Class 8 commercial trucks. The Hypertruck Electric Range Extender (ERX) is a long-haul, fully electric powertrain that will improve vehicle performance, reduce emissions and save on operational costs.

Supply chain leaders also implement supply chain assessments to identify inefficiencies and ways to reduce waste and expense. This leads to cost savings by improving visibility into the supply chain and identifying opportunities for more efficient logistics solutions. Assessments can also pinpoint opportunities for improving environmental impact, such as implementing green procurement systems.

The right technologies and modeling tools also enable higher efficiency and allow companies to optimize their warehouse practices to improve their profit margin. For example, Agility has a route-modeling tool that enables specialists to work with a nearly infinite number of variables and combinations. These include routes, schedules, inventory requirements, shipping modes, packing density, load configuration, and more. From this data, specialists can model various supply chain strategies and identify ways to optimize their shipping practices, as well as other steps in their supply chains.

How a green warehouse saves you money

Green practices often involve finding ways to improve efficiency through an optimized supply chain, which often benefits not only the environment but also a company’s bottom line. For example, when General Motors established a reusable container program with its suppliers, it reduced disposal costs by $12 million.

The following are some simple examples of how cost savings come about from green practices:

-

Decrease fossil fuel use:

Using less fossil fuel leads to cost savings, as long as you don’t accomplish this reduction by spending more on electric transportation or other methods. Practices such as consolidating orders into fewer shipments or optimizing shipping routes, for example, save fuel and fuel costs without requiring you to spend the savings elsewhere. -

Reduce hazardous materials use:

Many chemicals and other materials may be hazardous to humans or the environment. By minimizing reliance on these materials, such as solvents and paint, you save on costs associated with their handling and disposal. -

Use recyclable or reusable packing materials:

Although reusable packing materials may have a higher up-front cost, the ability to reuse them leads to savings in the long run. Recyclable packing materials or materials made from recycled products may be less expensive. -

Use technology to reduce waste:

Technologies such as robotic process automation or warehouse management tools lead to fewer mistakes, conserve time and energy, increase process efficiency, and reduce waste overall.

Saving money on operations through green warehouse practices

Warehouse storage can be expensive. Many of the reasons for high costs have their origins in practices that aren’t green. High energy usage, inefficient storage practices, and warehouse processes that result in waste cost money and hurt the environment.

Reducing these inefficiencies and sources of waste can make your warehouse practices greener and more cost effective.

Green warehouse practices

Companies can implement many practices within the warehouse environment that increase efficiency, save money, and promote sustainability. The following are some of the more common green warehouse practices:

-

Storage optimization:

Store products in a way that minimizes the total floor space you need for them. Also, consider stacking products on pallets that forklifts can easily handle and move to minimize any expenditures associated with moving these items. -

Inventory control:

Make sure to properly package, label, and store inventory. This minimizes damage, which saves you money while decreasing how much you send to the landfill. -

Cross-docking:

By transferring products directly from the supplier truck to the delivery vehicle bound for the customer, you use fewer resources in the warehouse. -

Recycling and reusing:

Reusing pallets and storage materials when possible saves money and helps the environment. Recycling old materials keeps them out of the landfill and saves on disposal fees. -

Energy-saving practices:

Increasing warehouse insulation, using energy-efficient or natural lighting, and automating lighting can reduce energy costs. -

Warehouse management:

Warehouse management systems (WMS) automate and streamline many processes within the warehouse, reducing expense and waste. For example, WMS can record inventory locations, direct employees where to store items, and calculate the most efficient sequence for picking items. Warehouse management software also facilitates shipping to customers from the closest warehouse, minimizing transportation use.

Benefits of improved resource efficiency

Practices that take place in the warehouse often impact and reflect practices throughout the larger supply chain. Therefore, improvements in warehouse operation often lead to improvements in shipping, handling, order management, and more.

Many of these green warehouse practices fall under the category of improving resource efficiency. In other words, the goal is to obtain the maximum useful work with the minimum amount of resources. Those resources may be human workers, energy usage, storage space, time, transportation, packaging, and so on.

For example, suppose a company plans to warehouse one hundred cubic feet of product. The warehouse needs to receive the product from the manufacturer, store the product, and then ship it to customers when they place an order.

However, this total volume is slightly over the maximum for a single forty-eight-inch by forty-inch pallet. If the company decides instead to ship ninety cubic feet at once, it can stack the product on a single pallet and improve resource efficiency. The company can then wait until demand calls for another ninety cubic feet of the product before it ships more to the warehouse. This minimizes storage space, as well as shipping and handling resources.

Cost efficiency of flexible warehousing

With the fast pace of today’s economy, many companies find that flexible warehousing solutions better meet their needs. Flexible warehousing is a warehousing strategy that enables companies to scale their warehouse space up and down by storing inventory in shared warehouse spaces on an as-needed basis. This also includes changing warehousing locations to meet customer demand.

What makes flexible warehousing green is that it only uses the necessary resources rather than securing space that goes unused. It’s also extremely cost effective because companies only pay for the space they’re using instead of reserving the maximum space they may need at all times.

Some warehousing providers specialize in providing flexible warehousing space, not by owning any actual real estate themselves, but by providing companies with open space in warehouses.

Often, 3PL providers bring the most efficient, cost-effective, and green solutions because they come with industry expertise, as well as optimal infrastructure. By handling the warehousing needs of multiple companies at once, they can strategically manage storage of all types, often with the help of industry-leading warehouse management software.

Determining the most cost-effective green warehouse practices

With so many different green techniques on the rise, how can companies determine the most cost-effective green warehouse practices? Fortunately, emerging technologies can provide data and models to predict the financial impact of adopting green practices. In addition, there are a wide variety of case studies that can help companies see what has worked well in similar industries.

Best practices for green warehousing

The first step in determining which practices will prove most cost effective requires using data and technology. The right technology and tools allow companies to estimate the environmental impact of new practices, as well as the associated increase or decrease to overall costs.

For example, Agility has a carbon measurement tool, which allows its customers to accurately offset estimated CO2 emissions. Since 2009, Agility has been providing customers with free carbon footprint reports that enable them to track and reduce the amount of emissions created in their supply chains.

Reducing carbon emissions often goes hand in hand with decreasing costs. Green practices typically involve cost-efficient measures such as using renewable energy, reusing resources, and cutting down on packaging materials.

Tools like warehouse management software make it easier for companies to manage and optimize their warehouse processes. Companies can also take advantage of other technology tools that automate packaging, handle procedures that reduce waste, and increase efficiency in a host of other ways.

Best green ways to reduce warehouse costs

Cost-effective green warehouse techniques aren’t one-size-fits-all; the best methods can vary based on factors like a company’s product and the target market. To decide on the best green methods for reducing your warehouse costs, it can be helpful to study how similar companies have found success in implementing green practices.

The following are some examples of practices that have helped companies realize significant cost savings: A sports apparel brand in Indonesia and the Philippines realized $2.2 million in savings by collapsing and stacking unused boxes for future use.

A Chilean retail company saw cost savings by using tracking technology. Purchase order visibility and real-time reports enabled proactive vendor contact and tracking, as well as improvements to processing efficiency.

Working with Agility helped a major electronics company meet a tight timeline by selecting a strategically located 14,500-square-meter facility in Algeria. By working with industry experts, the company procured all the necessary equipment, tools, and systems efficiently, minimizing waste and sales losses.

A global telecommunications provider created a goods-in-transit center that reduces air cargo weight, transport costs, and carbon emissions on shipments from mainland China and Hong Kong to India.

In general, following green packaging practices and using green packaging materials can help companies reduce costs while remaining environmentally friendly and reducing waste.

Inexpensively implementing green warehouse practices

Some companies avoid implementing green warehouse practices because they fear the cost of doing so. Even though companies may realize cost savings once those practices are in place, the problem lies in the up-front expenses companies must pay to change current practices.

For example, if a company decides to use reusable shipping containers, the new containers’ up-front cost might far exceed the cost of disposable ones. Even though it saves money in the long term, the opportunity cost may dissuade some supply chain managers.

However, by starting with simple steps that reduce waste and increase efficiency, it’s possible to realize long-term cost savings even with a small initial investment. Afterward, you can apply those saved funds toward other green measures with higher opportunity costs.

Tips for transitioning to green warehouse practices

Adopting green warehouse practices doesn’t have to happen all at once and doesn’t need to be an overwhelming proposition. Below are some simple tips that you can implement over time to transition to more sustainable practices:

-

Start small with recycling:

Make it a practice to send used packaging materials to a recycling center instead of the landfill. Work with a battery recycler to safely dispose of worn forklift batteries or other similar materials. -

Upgrade warehouse equipment with sustainable alternatives:

As older equipment wears out, replace it with new products that have lower energy requirements and maintenance needs. For example, choose electric forklifts and pallet jacks, as well as eco-friendly conveyor systems. -

Make lighting modifications:

Installing an energy management system for warehouse lighting allows you to only use lighting when needed. Replacing older bulbs and fixtures with newer energy-efficient LED fixtures can significantly reduce energy use and save money. -

Consider warehouse layout:

A poorly laid out warehouse can reduce efficiency. Look at the process for unloading, storing, and processing products. Identify ways to make the transitions as smooth as possible, without the need for continually rearranging pallets or moving materials across the warehouse floor. -

Consider warehouse locations:

A green warehouse is part of a larger green supply chain. Most of the total supply chain carbon footprint comes from moving items to and from warehouse locations and consumers. Strategically optimizing warehouse locations, storing products as close as possible to large customer centers, and optimizing shipping routes will cut emissions and costs. -

Consider other warehouse systems:

This includes everything from your heating, ventilation, and air-conditioning (HVAC) system to your choices for insulation and roofing. Improving insulation reduces heat transfer and saves on expenses related to heating and air-conditioning. A more energy-efficient HVAC system reduces usage and costs. And when it’s time to replace the roof, choose one that is bright and reflective. -

Transition to eco-friendly packaging:

Many options are available on the market, allowing companies to implement green packaging practices that meet their needs. This includes packaging made from recycled paper, mushrooms, cornstarch, organic fabric, and bamboo. These packaging materials are often inexpensive to produce and lightweight, which can reduce shipping emissions and expenses.

Inefficiencies to eliminate to make your warehouse green while on a budget

Making your warehouse green while on a budget requires careful planning. To begin, look over your entire supply chain management process to identify inefficiencies you can easily eliminate to the benefit of the environment, as well as your bottom line.

These inefficiencies may include things like the following:

-

Workflow disorganization:

Follow the path a product takes from manufacturer to warehouse/distribution center to consumer. Identify any hiccups along the way, such as delays in transfer, storage times that are longer than needed, or problems with order processing. Remedying the situation may only require simple process changes at no additional cost to you. -

Lack of carrier mode diversification:

Seek to continually build relationships with different carriers, and get quotes for other carrier mode options. By sticking with what you’ve always used before, you might be missing out on less expensive (and more environmentally friendly) options. -

Lack of proper demand forecasting:

By not having accurate estimates of consumer demands, it’s difficult to strategically and efficiently stock products in the right warehouse locations. This leads to using more space than needed, as well as extra transportation expenses. A small investment in quality forecasting software can lead to a significant payoff in the end. -

Excess packaging usage:

Examine your packaging usage and practices. You need to use enough packing materials to keep products safe during storage and transport, but overuse is simply waste. Identify ways to refine and optimize the use of packaging materials.

Eliminating inefficiencies often costs little except the time it takes to identify them and implement new practices. As a result, you might begin realizing cost savings immediately, and the environment will thank you as well.

Reducing costs and improving sustainability with Agility

The two key ways that a green warehouse provides a competitive advantage are by improving company image and decreasing expenses. Anytime you can accomplish the same objectives at a lower cost without reducing quality or other metrics, it’s in your best interest to do so.

One of the most efficient ways to implement green warehouse practices while reducing costs is to partner with a third-party logistics provider along with a world-class warehouse operator like Agility. Not only does Agility offer scalable warehousing and distribution capabilities worldwide, but it is actively working to build a greener and more equitable supply chain.

Agility has implemented multiple ongoing efforts to reduce hidden environmental and social costs associated with supply chain logistics. Independent sustainability analyst EcoVadis ranks in the top 5 percent industry-wide for environmentally friendly practices.

By partnering with Agility for your warehouse or supply chain solutions, you are working with an industry leader that actively engages in sustainability efforts to support the environment. Contact Agility’s warehousing team today to learn how it can help you save money while minimizing your impact on the environment.

What is green warehousing? And why is it important in the modern business climate? As the Information Age advances and as Earth continues to suffer the effects of climate change, well-informed consumers demand environmental and social responsibility from businesses, including green warehousing.

Sustainability in business—demonstrated by companies that operate with concern for natural and human resources—can mean increased customer loyalty. Incorporating green logistics into warehousing as part of the supply chain can also yield better business productivity and improve a business’s bottom line.

Applying green trends in warehousing offers nearly immediate return on investment (ROI) plus longer-term global improvements while satisfying stakeholders’ desires.

Today’s green warehousing practices

As warehouse managers consider green warehousing in today’s business climate, they need to know how to measure results and where to find available, effective products and practices.

Key performance indicators in green warehousing

In global supply chains, warehouses produce environmental pollution mostly from heating, cooling, and lighting. Generally, the bigger the warehouse, the larger the carbon footprint. Warehouse managers can measure the carbon footprint of their operations by considering key performance indicators: emissions, natural resource use, and amount of waste and recycling.

Studying total carbon dioxide emissions, as well as energy consumption, water consumption, and rate of product or material use, will reveal areas where companies can apply green initiatives.

For example, a warehouse with a high electricity bill might discover that alternative lighting sources—like natural light, automatic lights, or other renewable energy options—offer savings. Likewise, the discovery that a warehouse consumes large quantities of water from a natural source might inspire change. By installing water flow reduction mechanisms or a rainwater capture system, warehouses can reduce, offset, or optimize water use.

Green warehousing technologies and products available today

After assessing their warehouses to identify logistics solutions for environmental sustainability, businesses have various green warehousing products to consider that will promote sustainable logistics:

- A warehouse management system (WMS)

- Order-picking technology

- Bar coding

- Radio frequency identification (RFID)

A WMS allows for the digital coordination of stores, distribution centers, and warehouses while coordinating shipping and transportation. Better inventory control through a WMS means green warehouses can operate with the ideal amount of product, thereby reducing excess inventory and maximizing storage space.

Technology to enhance order picking through automation or digitizing can increase accuracy and speed up warehouse orders. Order-picking technology has the added benefit of reducing paper consumption.

Also reducing the need for paper are the sustainable distribution practices of bar coding and RFID. These technologies improve processes and increase the visibility of goods throughout the supply chain.

Additional sustainable products include skylights to let in natural light, ceiling fans to control warehouse temperature, energy-efficient lights and fixtures, green building materials, and building insulation. Eco-friendly warehouses reduce waste, another important principle of sustainable business.

Challenges facing green logistics today

Implementing green initiatives along the supply chain is difficult. But with the right tools and management practices, companies can confront any number of challenges:

- The vastness of the global supply chain: Supply chain logistics covers a wide range of shipping types, routes, sizes, configurations, and more. Lessening environmental impact across the entire network can be challenging.

- Fewer green solutions for warehousing: Compared to other parts of the supply chain, such as transportation, fewer green solutions exist for warehousing. Yet many of the available solutions prove effective, and the number of solutions is growing.

- The up-front costs of green warehousing solutions: These costs might prevent some operations from converting. However, the initial investment for green logistics often pays off with time.

Even if the path to green warehousing presents challenges, companies wanting to stand out from their competitors can prioritize sustainability to make a difference in the world and in their accounts.

Effectiveness of green warehousing

In a global market, businesses need to stand out from their competitors. Success hinges on providing consumers with what they want: companies that go green in all aspects of their operations. A green supply chain satisfies stakeholders’ desires while positively impacting operations and finances.

Green warehousing for the bottom line

Thanks to the digital proliferation of information, customers know the environmental impact of their buying habits. Those who want to reduce their carbon footprint seek out companies that prioritize green initiatives, from raw material source to warehouse to packaging to transportation. Conscientious consumers are willing to pay more for green products and services.

Businesses gain a competitive advantage by reducing environmental impact through supply chain management, including through green distribution. And publicizing details of these sustainable practices—such as using solar panels or green building materials—creates customer loyalty because the buyer perceives the company as environmentally responsible.

Benefits of moving to a green economy

Green logistics plays an important part in a larger undertaking: to move the world toward a green economy. A green economy focuses on low carbon emission, is efficient with resources, and is socially inclusive.

Benefits of a green economy include reduced pollution, enhanced efficiency of energy and resources, a slowdown in the loss of biodiversity, and preservation of the services that the ecosystem provides.

A successful green economy allows economic growth and improves people’s ability to coexist with nature. Economic growth might move slowly at first, but the benefits play out in the long run. Lasting benefits of sustainable development include reducing the risks associated with climate change, energy shocks, and water scarcity.

Green practices can also reduce poverty and help developing countries via new export opportunities. Businesses that embrace responsible supply chain practices stage themselves for success in emerging markets.

Results of a greener warehouse on a company’s ROI

Although the benefits of green warehousing might seem intangible or too far off, supply chain managers who invest in going green see a fast ROI.

Energy-efficiency measures, such as switching lighting sources to reduce electricity consumption, have a quick payoff. Installing a WMS could deliver an ROI in a matter of months.

Importance of green warehousing

Because supply chains are a major source of environmental impact in the consumer sector, sustainability in the industry can have a positive impact on the environment.

Importance of green practices for warehouses

As stakeholders demand that businesses reduce their carbon footprints, green practices become increasingly important for eco-friendly warehouses. They must keep up with government regulations, meet insurance requirements, and satisfy the demands of customers.

A green warehouse aims to lessen its environmental impact through practices such as an automated warehouse, lean warehousing, and green building.

Green warehousing to reduce a company’s environmental footprint

Companies can focus on decreasing the carbon footprint of their warehouses through various methods:

- Decreasing demand for electricity: Companies can accomplish this by reducing heating, cooling, and lighting demands, by generating power on site, or by taking advantage of energy management systems.

- Reducing waste: Companies can limit waste by ensuring efficient inventory management, going paperless, and using eco-friendly packaging.

- Building warehouses efficiently: By cutting back on the size of warehouses, building vertically, or using green building materials, companies can diminish their footprints on the land itself.

Goals of green warehousing

As a strategy, sustainable logistics aims to reduce environmental costs, resource waste, and business risks—moving the world toward a green economy. And with a strategic approach to supply chain sustainability in the warehouse, a company can accomplish many of its green goals.

The future of green warehousing

The warehousing industry continues to evolve, finding new ways to improve operations and reduce environmental impact. Green warehouses, whether new or retrofitted, have allowed leaders to emerge among warehouse operators, and the principles they use can help transform warehouses around the world.

Projected features of new green warehouses

New green warehouses prioritize efficiency and sustainability. Features of eco-friendly warehouses include the following:

- Recycling areas

- Solar panels or other power-generating features

- Xeriscaping and drought-tolerant plants

- Green building practices

- Skylights

- Roofs and walls that are appropriate for the climate

- Low-emitting paint

- Energy-efficient lighting

- Regionally sourced building materials

Leaders in the green warehouse movement